Solutions

Meridian Technology offers professional poultry slaughterhouse design services, complete with modern chicken slaughterhouse plans, layout drawing. Our solutions help clients plan and build efficient, hygienic, and scalable poultry processing plants tailored to production needs and local standards.

- Mobile Chicken Slaughterhouse&Small Scale Poultry Slaughter Line

- Complete Poultry Slaughter Line and Chicken Processing Plant Solution

- Fish Processing Plant&Fishing Boat Seafood Cooling

- Chicken Meat Blast Freezer/Quick-Freezing Cold Storage Room

- Meat/Fish/Fruit/Vegetable Storage Cold Storage Room

- 20FT&40FT Containerized Cold Room

- Fruit and Vegetable Preservation&Beer and Beverage Cooling

- Complete 500 BPH Slaughterhouse Poultry Processing Line Solution

- Poultry Slaughterhouse 1000-1500kg Per Hour Chicken Feet Processing Line

- 1000BPH Compact Chicken Processing Plant

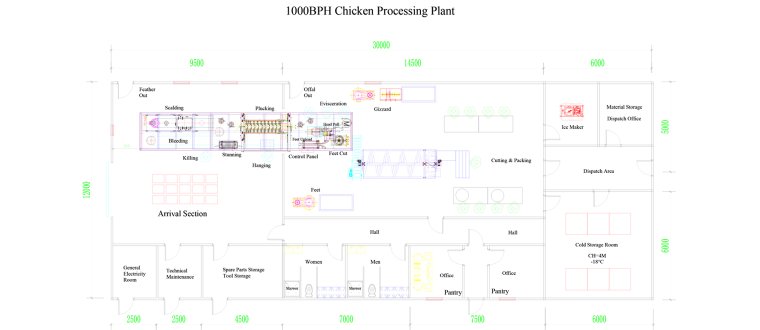

1000BPH Compact Chicken Processing Plant

Professional Overview

The 1000BPH Compact Chicken Processing Plant, developed by Meridian Technology Co., Ltd., represents the next generation of automatic poultry slaughtering and processing equipment.Upgraded from our popular 300–800BPH compact line, this system increases throughput to 1,000 birds per hour, offering greater productivity within a modular and space-saving layout.It is the ideal choice for small and medium poultry slaughterhouses, mobile slaughter units, and regional processing centers seeking a balance of capacity, hygiene, and cost efficiency.

Integrated Poultry Processing Solution

This complete poultry processing plant covers every stage of modern chicken production —

from live bird reception, stunning, bleeding, scalding, and plucking, to evisceration, chilling, cutting, and packaging.

The engineering layout, based on the Meridian 1000BPH plant design, ensures a unidirectional processing flow separating “clean” and “non-clean” zones to meet HACCP and ISO 22000 hygiene standards.

Each zone is carefully configured for maximum efficiency:

Live Bird Area – equipped with an overhead conveyor and stainless steel shackles for continuous hanging.

Stunning & Bleeding Section – humane electric stunner with closed bleeding trough.

Scalding and Plucking Zone – automatic stainless steel scalding tank and high-efficiency pluckers.

Evisceration Area – optional manual or semi-automatic setup for flexible operation.

Chilling System – air or water chilling integrated with a flake ice machine for temperature control.

Cut-up and Packaging Room – complete with stainless steel worktables, conveyors, and vacuum packing units.

Auxiliary Areas – including boiler and steam system, cold room, wastewater treatment, and technical control room.

Engineering Highlights

Compact Modular Design – The plant adopts a container-sized modular layout, minimizing civil work and installation time, ideal for export and on-site setup.

High Capacity in Limited Space – 1000BPH throughput achievable within <600m² plant area.

All Stainless Steel Construction (304/316) – Durable, hygienic, and corrosion-resistant for long service life.

Integrated Ice & Cooling System – Dedicated flake ice maker supports rapid chilling and product freshness.

Turnkey Utility Integration – Steam generation, water systems, and drainage included in one engineered layout.

Halal & International Standard Compliance – Designed to meet Halal, EU, and HACCP processing requirements.

Complete Turnkey Poultry Plant by Meridian Technology

As a professional poultry equipment manufacturer, Meridian Technology Co., Ltd. provides end-to-end poultry slaughterhouse solutions —from layout design, equipment manufacturing, and installation supervision, to technical training and after-sales service.Each project is customized to meet local regulations, processing volumes, and space conditions.With a proven track record in Asia, Africa, and Latin America, Meridian delivers efficient, export-ready poultry slaughtering systems trusted by global clients.